Manufacturing Capacity

Chan Way has continuously optimized the manufacturing process, adopted intelligent systems "integrated ERP system", "collaborative APS system", and "execute automated production line" to provide real-time and transparent WIP information on the production line. When there is an abnormality in the production process, it can be notified immediately. Import monitoring and statistical analysis of product manufacturing process related information can reduce processing time and ensure product quality.

In order to cooperate with the introduction of the APS system, and to effectively implement e-management, the Manufacturing Execution System (MES) is introduced in the planning to improve the mobility of industrial management. It is hoped that improvements from the aspects of "information collection barcode", "operation process standardization", and "production management automation" can assist management units to make correct decisions, and further establishes smart factories, enhance future competitiveness and achieve Industry 4.0.

One-Stop Manufacturing Process

Grinding, cutting, electric discharge, wire cutting, milling machine to surface treatment

Grinding & Optical Profile Grinding

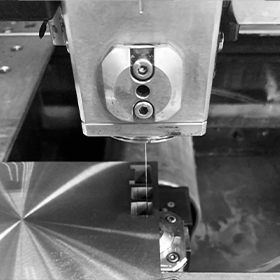

Wire Cut

Electrical Discharge Machining

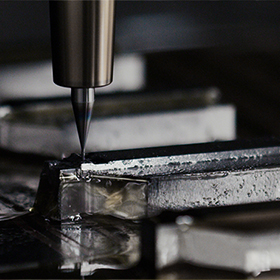

High-Speed Milling Machine

Precision Processing Equipment

- Precision micro-high speed milling machine (Rokuroku, Fanuc)

- Precision forming electric discharge machine (Sodick)

- Surface grinding machine (Mitsui)

- Wire cutting machine (Sodick, Seibu)

- Optical grinding machine (WAIDA)

- Injection molding machine (Fanuc, Sumitomo, Nissei, FCS (50ton~300ton)

- Punching machine (Kyori)

Production Field

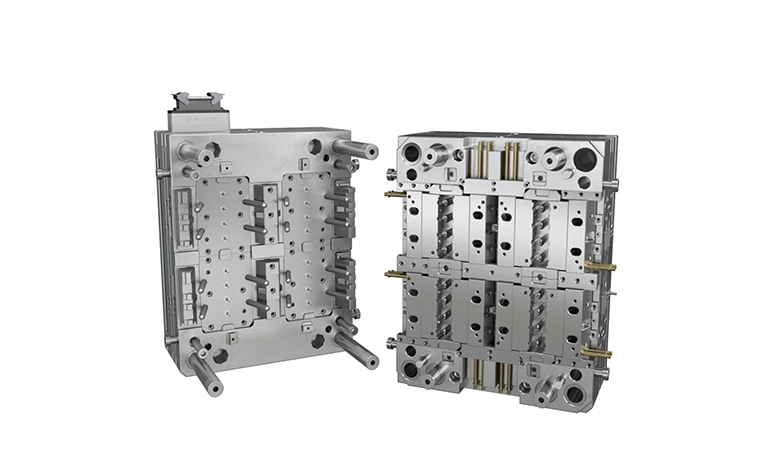

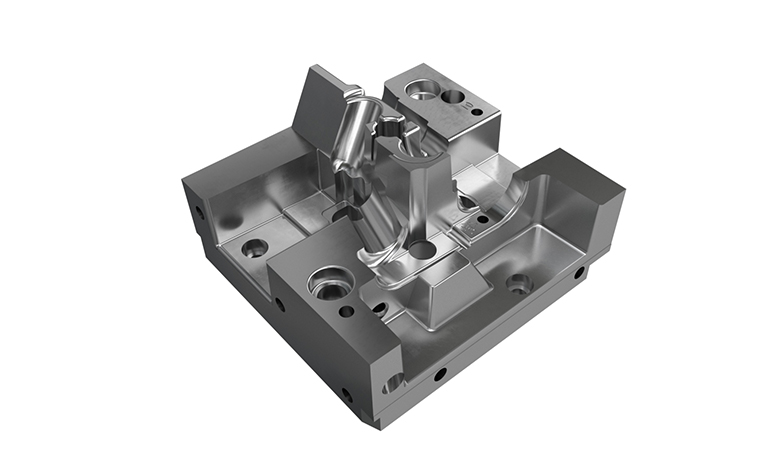

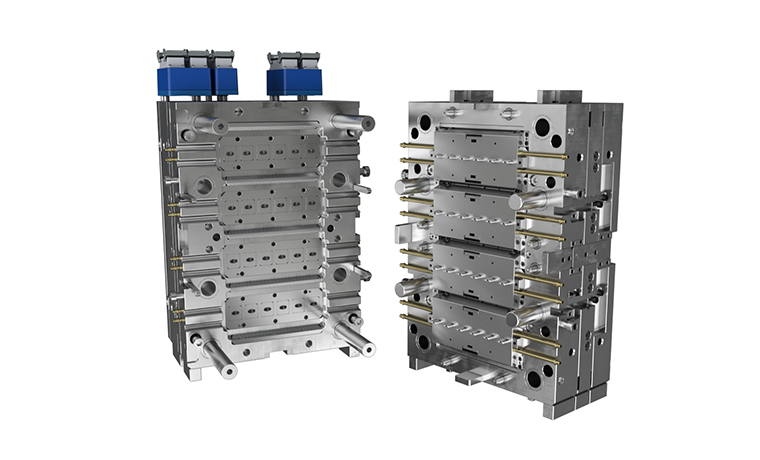

Mold Design Capability

Plastic injection mold, metal powder metallurgy injection mold

Injection Molding Capacity

The injection mass production environment of a 100,000-class clean room, combined with automated production, inspection, assembly, and packaging system management.

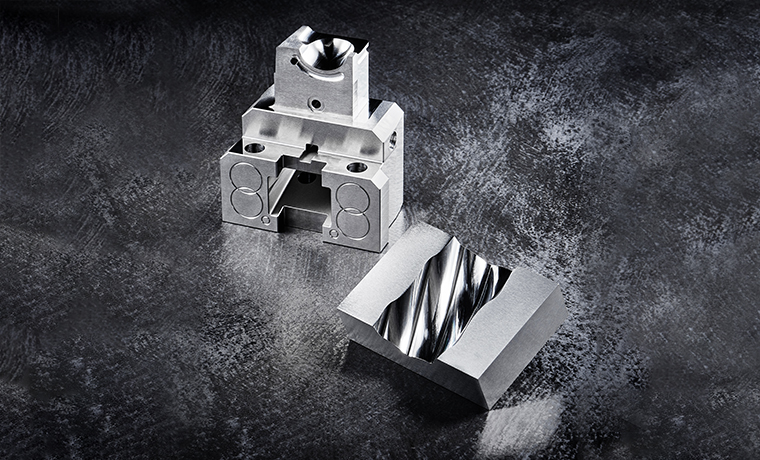

Precision Machining Parts

Die parts, plastic mold parts, mechanical parts

Precision

Machining accuracy ± 0.002 mm

Precision Machining Software

Surface Treatment Technology

Electroplating (titanium, nickel, chromium, zinc, titanium silicon, aluminum titanium, anode, blacking, nitriding, DLC, sandblasting, biting, etching, polishing, etc.).

Order Production Process

Customization Of Precision Parts

Customer provides picture (2D/3D)

Chan Way Evaluates Processing Technology & Quotation

Customer Places Order

Process And Manufacture

Inspect Quality

Order Capacity

Monthly production capacity of about 30 sets of mold development and manufacturing