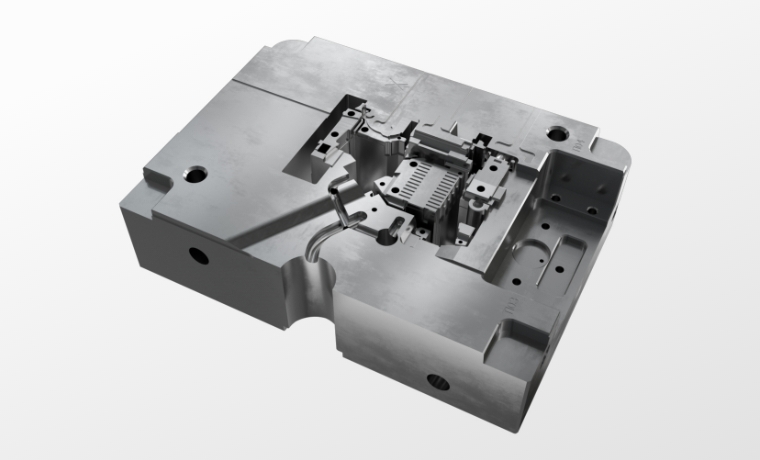

Customized Precision Machining

01Precision Parts Machining

As a precision machining company, Chan Way has professional manufacturing capabilities and we can provide production customized services based on customers’ needs, such as custom CNC machining services.

With precision machining capabilities, high-quality metal or plastic components are manufactured, and the manufactured components are then processed through surface treatments. After processing, the product quality, product stability, and product life cycle are further improved. Professional process experiences and team combined with software and hardware development capabilities allow us to commit to creating a good customized experience for customers.

Various industries and various machines have various unique parts requirements. If you have customized requirements for parts with special materials, styles, and specifications, you can contact Chan Way. We can further provide you with the best service, such as EDM machining services.

Our services From R&D design, production, testing, to assembly, and other complete manufacturing solutions, we can meet the needs of different industries. We have the experience and capability to meet the market's demand and provide a suitable solution, we can offer customized design and OEM/ODM service plans for the market.

Finding reliable precision machining companies with high standard EDM machining services and custom CNC machining services? Just feel free to contact Chan Way at your time!

OEM/ODM Service

Chan Way has an excellent team that can provide R&D technical guidance and services. With a complete production line equipment and quality control system, we provide customers with high-mix, low-volume production of OEM/ODM services.

Application Industry Scope of Automated Processing Products

- 3C electronic products, communication equipment (mobile phones, computers, watches, sensors)

- Auto parts (connectors, sensors, clutches, micro motors)

- Medical industry (blood sugar testing, auto-injector)

Customized Order Evaluation

The production time will be evaluated according to the product process requirements, and the delivery time will be evaluated reasonably during the inquiry stage. The minimum order quantity is 1pcs.

Overview of Customized Processing

Precision processing (grinding, cutting, electrical discharge, wire cutting, milling machine).

Machinable Materials

- ASSAB: XW-10, XF25, ASSAB 8407, ASP23, ASP30, ASP 60

- BÖHLER: K340, K390, S290, S790, M340, M368, M390

- CERATIZIT: H40S

- UDDEHOLM: RIGOR, Viking, VANADIS 4 EXTRA, ELMAX, STARVAX ESR, RAMAX HH, ORVAR, DIEVAR, MOLMAX

- ThyssenKrupp Material France: TSP3W

- DAIDO: DC53, PD613, SUS440C, S-STAR, NAK55, NAK80

- HITACHI: HPM31, SLD, DAC, YXM1, YXR3, YXR7

- EVERLOY: KD20

Post-Processing Customized Parts

Electroplating (surface treatment processes such as titanium, nickel, chromium, zinc, titanium silicon, aluminum titanium, anode, blacking, nitriding, DLC, sandblasting, biting, etching, polishing, etc.)

02Automation Electrical Discharge Machining Processing Line

The team of Chan Way constantly improves its technology and introduces relevant professional machines and equipment. It is committed to integrating the upstream and downstream supply chains. With years of industry experiences, it provides customers with more complete manufacturing recommendations and more comprehensive OEM/ODM automation production services.

Automation Electrical Discharge Machining Processing Line Specification

EDM Machine

Sodick AP1L

Axis stroke X×Y×Z (mm)

200 x 120 x 200

Robotic Arm

FANUC M-710ic/45M

Maxima Loading Weight

45 Kg

Electrodes Chamber volume for CMM Measurement Area

80 pcs

Electrodes Chamber volume for EDM Area

480 pcs

Artifact Chamber volume for EDM Area

96 pcs

CMM

Hexagon / Global Performance

Accuracy for CMM

1.5 μm

Processing Accuracy

2 μm

03CNC Automated Production Line

Facing the trend of rapid industrial innovation, we have adopted the advanced automated processes and management systems to consolidate market competitiveness to meet the changing needs of customers, and have a professional clean room to provide a high-standard production environment. By introducing industry 4.0 thinking, factory automation systems, and automated robotic arms, it has increased the efficiency of the process and enhanced precision manufacturing capabilities. Upgrade the industry and create more value-added services and products.

Overview of CNC Automated Production Line

Automated Processing Technology

CNC high-speed milling machine ultra-precision micro-processing automation.

Overview of Automated Processing Capabilities

- Processing Specifications: 800x600x400mm Max.

- Machining Accuracy: ±0.002mm

Advantages of Automated Processing Capabilities

Provide stable delivery, quality, cost batch processing services sustainably

CNC Machining Automated Production Line

- Accuracy: ±0.002

- Mirror surface nanometer (Ra0.018um)

- Spindle Speed: 60,000/min

- ATC Capacity: 60 (automatic switching tool magazine)

- AHC Capacity: 40 (electrode compartment with automatic switching)

Machinable Materials

- Plastic tool steel (pre-hardened steel, full-hard steel, powdered steel, aluminum alloy, copper alloy, stainless steel)

- Hot work tool steel (general hot work steel, high performance hot work steel)

- Cold work tool steel (general tool steel, high speed steel, powder metallurgy tool steel, powder jig high speed steel)

- Tungsten carbide (fine particles, ultrafine particles, fine particles, medium particles)

An automated production line is an accurate, fast, and stable flow of production that increases production time and lowers the cost of the manufactured products whilst reducing room for human error and providing a consistent output, and Chan Way can do that.